Alternator Working Construction and Synchronizing

In this article we will know about the alternator working construction and synchronizing. we will also studied about the main part of alternator .we will also studied about the synchronizing of alternator . we study about the parallel operation of alternator.

Alternator Working Construction and Synchronizing

Working of Alternator

It is a machine which converts mechanical energy into electrical energy. Since,this machine generates alternating currents, so it is called alternator.

Working principle of Alternator

The alternator works on the principle of Faraday law of electromagnetic induction. When a conductor is rotated in a magnetic flux an, EMF is induced in that conducts due to the change in flux.

The condition for generating EMF is either the flux should be in motion and conductor stationary or conductors in motion and flux stationary.

In larger size generators flux is kept revolving and conductors stationary.

Classification of Alternator

According to their construction, alternator is classified into two parts

1 Revolving armature type alternator

2 Revolving field type alternator

Revolving Armature Type Alternator

- It has stationary field poles and revolving armature.

- It is usually of relatively small kVA capacity and low voltage rating.

- It resembles a DC generator in general appearance exact that it has slip-rings instead of a commentator.

- The field excitation must be dc and therefore, must be supplied from an external DC source.

Revolving Field Type Alternator

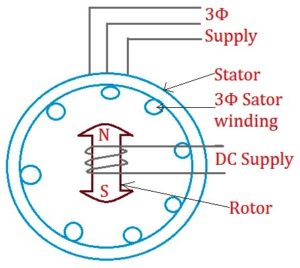

It has a stationary armature or stater inside of which the field poles rotate.

Most alternators are of the revolving field type in which the revolving field structure or rotor has slip-ring and brushes to supply the excitation current from an outside DC source usually the field voltage is between 100V and the amount of power delivered to the field circuit is relatively small.

Advantages of the Revolving Field Type Alternator

- The armature winding are more easily braced to prevent deformation under the mechanical stresses due to short circuit currents and centrifugal forces.

- The armature (stater) winding must be insulated for a high voltage, while the voltage of field circuit is low (100 V to 250 V). it is much easier to insulate the high winding when it is mounted on the stationary structure.

- Only a small amount of power at low voltage is handled by the slip-ring contacts.

- It is easier to build and properly balance high speed rotors,when they carry the field structure.

- The armature winding is cooled more readily,because the stater core ca be made large enough and with many air passages or cooling ducts for forced air circulation.

Working Construction of Alternator

Stater working construction

The stater of an alternator consists essentially of a cast iron or a welded steel frames supporting a slotted ring made of soft laminated steel sheet purchasing in the slots of which the armature coils are assembled.The lamina tors are annealed and are insulated from each other by a thin coating of oxide and an enamel.

- Open slots are used,permitting easy installation of stater coils and easy removal in case of repair.

- The coil are shaped much like the coils of a DC generator,the two sides of the coil being approximately a pole pitch apart. All coils are alike and therefore,interchangeable.

- A fractional rather an integral number of slots per pole is often used in order to eliminate harmonics in the waveform.

Rotor Construction working

The revolving field structure is usually called the rotor.

There are two type of rotor

- Salient pole type rotor

- Smooth cylindrical type rotor

Salient Pole Type Rotor

This type of rotor is used for show speed machines which have large diameters and small axial lengths.

- The pole are made of thick steel lamination riveted together and attached to a rotor by a dovetail joint. The over hang of the pole gives mechanical support to the field coil.

- In most of the alternators, where the oscillation or the limiting effect is very high the damper winding in the pole faces is provided. The copper bars short-circuited at both ends are placed in the specially provided holes.

Smooth Cylindrical Type Rotor

This type of rotor is used for alternators, which are coupled to steam turbines which run at very high speeds. To reduce the peripheral speeds of the alternator the diameter of the rotor is reduced and avail length is increased. The numbers of polle of the rotor are two or four.

- Those are made from solid forging of alloy steel. The outer periphery of rotor has slots in which the field winding is placed.

- Cylindrical rotor machines have always horizontal configuration.

Synchronizing of Alternators

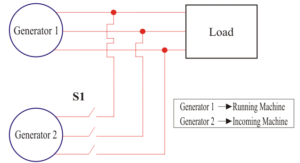

The process of connecting an alternator on parallel with another, then alternator is called is called synchronizing.

The various advantages of running alternator in parallel.

- Better continuity of supply can be maintained than running a single unit.

- Alternators give maximum efficiency, because of running at full load.

- Repairing of a unit is more convenient and economical.

- The additional unit can be installed and when required with the increase of load

- The cost of stand by unit is less.

Condition for Synchronizing

The following conditions must be fulfilled before synchronizing

- The voltage of both the alternator must be same, i.e., the running voltage of the alternator to be synchronized and the running voltage of the bus-bar must be same.

- The frequency must be same.

- The phase sequence should be same.

Alternator Synchronizing

The following are the methods of synchronizing

- Dark lamp method

- Bright lamp method

- Dark and bright lamp method

- Synchronous scope method

Equipment Required for Synchronizing

- Double range voltmeters

- Double range frequency meter

- Synchronous scope

- Lamps for dark and bright lamp method

These are alternator working construction and synchronizing.

Load sharing of Alternators

The load sharing of the alternators in parallel can be achieved

- By changing the excitation current.

- By increasing the steam supply of one alternator.

Voltage Regulation Of Alternator

When an alternator is subjected to a varying load, the voltage at the armature terminals varies to a certain extent, the amount of this variation determinate the regulation of the machine. The numerical value of regulation is defined as the percentage rise in voltage when full load at the specified power factor is switched off, the excitation

Determination of Voltage Regulation

The following indirect methods are used to determine voltage regulation

- Local or regional power use may exceed the power of a single available generator.

- Parallel alternators allow one or more units to be shut down for scheduled or emergency maintenance while the load is being supplied with power.

- Generator are inefficient at part load, so shutting down one or more generators allows the remaining load to be carried with less machines that are efficiently loaded.

- Load growth can be handled by added machines without disturbing the original installation.

- Available machine prime movers and generators can be matched for economic first cost and flexible use. these are working construction and synchronizing of alternator.

Load Distribution of Alternators

We have the following distributions of load

- Effect of change in driving torque.

- Effect of change in excitation

It may show that

- Amount of load taken up by an alternator running in parallel with other machines is solely determined by its driving torque, i.e., by the power input to its prime-movers.

- Any change in its excitation merely changes its kVA output but not its kW output. In other works, merely changes the power factor at which load is delivered.

Hence these are alternator working construction and synchronizing . we have also studied about the parallel operation of alternator and load sharing of alternator.if you will find in above article you must comment below in comment box.