Power Plant Economics study

In this article we will know about the power plant economics. Which means we will study about which type resources are required for start a new power plant.

Power Plant Economics

1. COST OF ELECTRICAL ENERGY

It is most important factor of power plant economics.

The generation cost per kWh of energy depends. On the cost covering the purpose, installation and erection of equipment, cost of fuel, labor, repair etc, The generation cost can be divided into fixed cost i.e. the cost which depends on the extent of plants investment and financial rates and remain a fixed one irrespective of the amount of energy generated and operating cost which includes the expenditure for fuel, labor, supervision etc. The operating costs of a plant are generally variable in magnitude and depend on the amount of energy produced.

2. CAPITAL COST OF PLANTS

Capital cost of plant is also a main factor to know about the power plant economics.

The capital cost of a plant includes the preliminary cost, cost of land and other real estate, cost of design and planning, cost of building and equipment, cost of transportation, erection and installation of equipment and overheads etc. the cost of a steam plant located near a river where adequate supply of cooling water is available would be less than that of one in which cooling towers or ponds are needed for cooling water.

In addition to the costs mentioned above, the capital cost of a hydro-electric plant includes the costs of dam, earth work, excavation,rail head,highways and other civil works and compensation to property owners whose lands would be submerged in the reservoir.

The capitals costs of plants vary very widely even for similar types of plants and depend to a large extent on the market conditions. The range of cost for hydro plants is greater than that for steam plants, the reason being that in case of steam plants, only about 15 percent of the cost is influenced by topographical condition. Whereas in the case of hydro-electric plants, around 75 percent of the cost is affected by these conditions.

In general a large plant costs less per KW of installed capacity than a small one. A plant having a small number of large sexed units costs less than a plant of the same total capacity but having a large number of small sized units. Roughly the capital costs are around Rs. 3000 to 35000 per KW for diesel, gas and steam plants, Rs 4000 to 60000 per KW for hydro-electric plants and Rs. 15000 to 60000 per KW for nuclear plants.

3. Annual fixed cost of power plant

In this topic we will know about total fixed cost in one year of any power plant. We will discuss about the various type fixed cost, which is essential to know for understand of power plant economics.

Components Of power plant

The annual fixed cost of a plant consists of interest, taxes, insurance, depreciation, managerial and general maintenance cost and rate of return.

A. Interest, taxes and insurance.

The capital for setting up the plant may be provided by the government (or the private owner) or acquired through loan form financial institution or acquired by the sale of stuck or bonds or both. The annual interest and dividend gave to be included in the total cost of service. The utility may have to pay various taxes to town, state and federal authorities. However, only the taxes which are a function of the capital investment should be included in the fixed costs and the other taxes should be included in the operating costs.

Every well managed utility has to incur expenditure on insurance against accident to equipment and personnel. The list of risk and insurance is usually very long. Example, fire, flood, hail, earthquake explosion public liability, workmen compensation etc. the insurance may be obtained from insurance companies or if the enterprise is very big. It may be self-insured. This is done by setting aside a reserve fund, out of earnings, every year. Such an insurance fund is quite district and separate from the depreciation fund.

B. depreciation of power plant

Every equipment deteriorates or depreciates due to wear and tear, corrosion. Weathering etc. in addition, the equipment may become inadequate due to increase in demand or become absolute and may need replacement by a modern one.

It is necessary for the financial stability and safety that the capital of an enterprise must remain intact. When a plant becomes useless, funds must be available to replace it. The methods for calculating depreciation are discussed in section 3.7.

C. Managerial and general maintenance costs.

part of total wage bill of a power plant is constant irrespective of the amount of energy. These costs are proportional to the size of the plant and the equipment and should be included in fixed costs.

D. Rate of return of power plant

An undertaking can be successful only if it earns profit. It is a private limited company and has floated shares or bonds, it must pay a good dividend so that the value of the shares may be high and the undertaking may be successful. Therefore, a certain rate of return on investment should be taken into account in calculating the annual fixed costs.

4. Operating cost or production cost

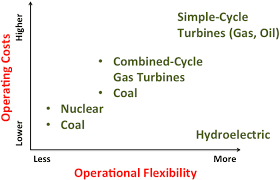

The operation of a plant means expenses which vary with the extent of operation or the amount of energy produced. such expenses are included in the annual operating costs, the items which constitute operating costs are: fuel , operating labor, maintenance costs and supplies. in steam, diesel and gas plants,the operating costs form a major portion of total annual cost whereas in hydro, nuclear and solar plants,the fixed costs overshadow the small operating costs.

(a) Fuel.

This is largest item of expense in thermal, diesel and gas turbine stations. The fuel may be in the form of coal, oil, natural gas, wood scrap etc. The cost of fuel depends on the type of fuel, calorific value, availability and freight rates. The annual fuel cost of a station depends on the amount of energy produced, the efficiency of the plant and the unit price of fuel. The fuel cost of station can be anticipated if (i) a realistic load model is known for each future week or month in the planning period (ii) the units are committed to supply load in a manner that reflects actual operating procedures and conditions.

(b) Operating labor

The operation of a plant needs staff and labor. In a steam plant labor is needed for unloading and storing of fuel, disposal of refuse, operation of boiler, prime mover etc. The increasing application of automatic equipment and the increase in unit sizes have reduced the number of men required to operate a plant by a considerable amount. Hydro plant and diesel plants need less labor than steam plants.

(c) Maintenance cost. of power plant

Every plant needs preventive maintenance (inspection cleaning repair, overhauling etc.) to keep it in good condition. The maintenance cost can be further subdivided into the cost of material required for maintenance and cost of labor. To estimate the maintenance cost of proposed plant, the information from a similar plant in an analogous situation can be used.

(d) Supplies.

This item includes the cost of water for makes up, cooling purposes and general use, lubricating oil and other consumable materials.

Hence this is power plant economics study if you have find any incorrect in above article you must comment below in comment box.