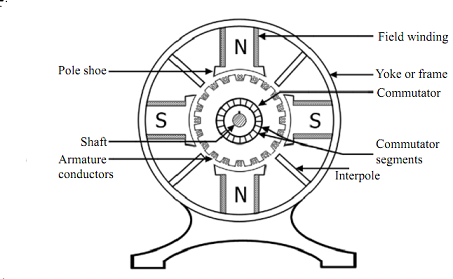

Construction of DC Generator

1. Magnetic Frame or Yoke

2. Pole Cores and Pole Shoes

3. Pole Coil or Field Coils

4. Armature Core

5. Armature Winding or Conductors

6. Commutator

7. Brushes and Bearings

Construction of DC Generator

1. Magnetic Frame or Yoke

The outer yoke or frame is used for two purpose.

- It provides mechanical support for the poles and also provides mechanical strength to generator machine. It acts as a protecting cover for whole machine.

- This carries the magnetic flux produced by poles. In small size generator yoke are made of cast iron but in large size generator it is made of cast steal.

2. Poles Cores and Pole Shoes

- They spread out the flux in the air gap and also they reduced the reluctance in magnetic path.

- They support the field coil (exciting coils).

There are two main types of pole constructions.

- The pole core is made from cast iron or cast steal but pole shoe is laminated.

- In modern design, the whole pole cores and pole shoes are made of thin lamination of annealed steal which are riveted from hydraulic pressure.The lamination thickness varies from 1 mm to .25 mm.

3.Pole Coils or Field Coils

Pole coils or field coils, which consist of copper wire or strip. When current flow in these coils they electromagnetise the poles and the poles produces the necessary flux that is cut by revolving armature conductor.

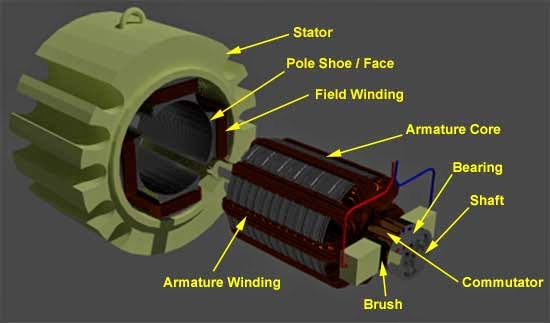

4. Armature Core

Its most important function is to provide a path of very low reluctance to the flux through the armature from a North pole to a South pole.

Its is cylindrical or drum shaped. Field coils lies in Armature core. Armature core holds Armature winding and provide path of low reluctance.

5. Armature Windings

In DC generator there are two types of windings, first one is Field winding and second is armature winding. The armature winding is usually former-wound. In Armature winding EMF induced when this rotate and its circuit will closed so current will flow in this winding.

6. Commutator

The commutator main work is to take input AC (alternating current ) and give output DC. The commutator is to facilitate collection of current from the armature conductor.

We take output DC from commutator by using carbon brush. It works like a rectifier but its input and output magnitude are being same so it is also a very useful part of DC generator.

7. Brushes and Bearings

Brushes

The brushes which collect current from commutator are made of carbon or graphite. Its shape in rectangular block. Brush are made of carbon or graphite because its friction coefficient is better than other. So carbon brush take supply from commutator and give output to terminal of generator.

Bearings

In DC generator bearing are used to reduces losses of friction and other mechanical losses. So its mainly used for reduce mechanical losses. It lies at both ends rotor and making rotor essay for rotation.