Integrated Power Generation and Generation planning

Intigrated power generation and generation planning In this article. we will also know about the benefits of integrated power generation and steam turbine cogeneration system.By this article we will know how many types of steam turbine. we will discuss about the back presser steam turbine and extraction condensing steam turbine. we will also know about the open cycle gas turbine and closed cycle gas turbine.

Integrated Power Generation and Generation planning

Now we will starting to know about the Integrated power generation and generation planning.

Generation Planning Introduction

The generation planning process beings with the electricity load-demand forecast. The demand for electricity initiates actions by utilities to add generation, transmission or distribution capacity. Because of the long lead-time required to construct new facilities, decisions are often to be made 2to 10 years in advance. it shows that integrated power generation and generation planning. Now we are going to understand about the integrated poer generation and generation planning.

The three major aspects to be dealt with and considered in generation planning process are:

- Growth of the power generation capacity to meet the demand pattern In accordance with the principles of sustainable development. Sustainable development of our country is our ultimate goal, which encompasses economic development of our country, is our ultimate goal, which encompasses economic development environmental quality and social equity. This would also ensure that development takes place to fulfill our present needs without compromising the needs of our future generations.

- To fulfill desired operational characteristics of the system (to meet varying demand) such as reliability and flexibility.

- Most efficient use of resource i.e. addition of latest technological advancements in Coal based generation, Combined Cooling, Heating and Power (CCHP) and Distributed Generation.

The above aspects have been considered within realms of feasibility, while drawing up this National Electricity Plan along with the economics and status of the various projects.

Integrated Power Generation and generation planing

Unlike any other industry, the electric supply industry is one in which there has to be an instantaneous balance between supply and demand. Electricity cannot be stored and therefore the grid must stay balanced at all times. Through the integrated powder generation we are trying to balance supply and load side through integrated power generation the uneven distribution of resources calls effective interconnection between various regions to allow inter regional exchange of power so as optimize the economics of operation. Power planning is generally done on a regional bias, in that integrated power generation is very important, and efforts are made to make them self-sufficient. In India, five regions have been recognized Western, Eastern, Southern and Northeastern. By this nature resorce produce integrated power generation and generation planning.

There is big difference between on region and another which results in different peak load. Integrated power generation helps to fill the difference of that region and supply-demand. The operation of each regional grid is controlled by regional electric grid. By this we can easily know about the integrated power generation and generation planning.

Benefits of Integrated Power Generation

- Optimum utilization of hydro, thermal and nuclear power station.

- Reduction in installed capacity requirement due to diversity in peak demand of various constituent systems.

- Reduction in spinning reserve requirement.

- Better frequency control and stability due to high inertia.

- Reactive power planning in the region.

These are some benefits of integrated power generation and generation planning.Integrated power plants do not necessarily have it be islands that are disconnected from the grid. In fact, it is often the case that the demand of the industrial process exceeds the capacity of the captive plant and power must be taken from the grid to make the difference. In addition, there must be some provision to bootstrap the integrated process into operation.

Methods of Cogeneration System

Now will study about different methods of cogeneration system which is very helpful to understand about the Integrated power generation and generation planning.Here are Three types of Cogeneration system below.

- Steam Turbine Cogeneration System

- Gas Turbine Cogeneration System

- Reciprocating Engine Cogeneration System

1. Steam Turbine Cogeneration System

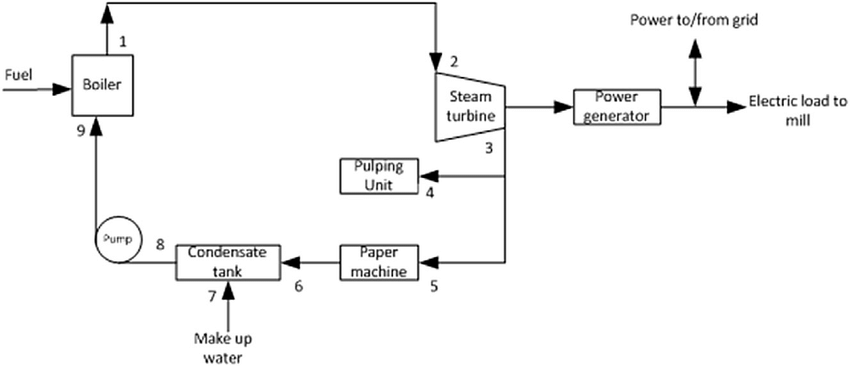

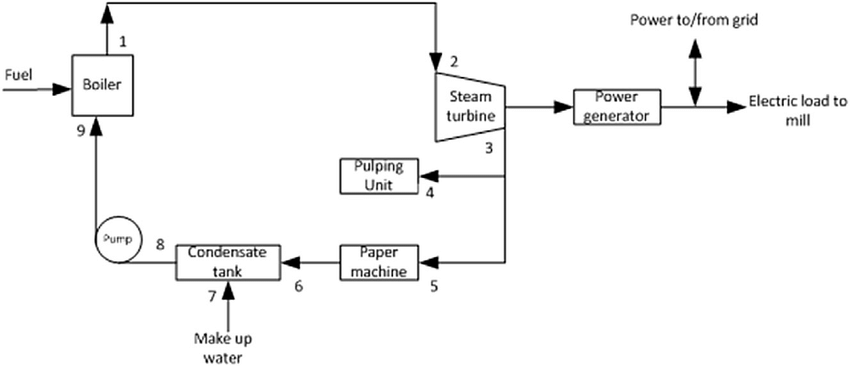

Steam turbines are one of the most versatile and oldest prime mover technologies still in general production. Power generation using steam turbines has been in use for about 100 years, when they replace reciprocating steam engines due to their higher efficiencies and lower costs. The capacity of steam turbines can range from 50 kW to several hundred MWS for large utility power plants. Steam turbines are widely used for combined heat and power (CHIP) applications. The two types of steam turbines most widely used are the backpressure and the extraction condensing types. The choice between backpressure turbine and extraction-condensing turbine depends mainly on the quantities of power and heat, quality of heat and economic factors. The extraction points of steam from the turbine could be more than one, depending on the temperature levels of heat required by the processes. cogeneration is also provide benifit of intigrated power generation and generation planning.

-

Back Pressure Steam Turbine

A backpressure steam turbine is the simplest configuration. Steam exits the turbine at a pressure higher or at least equal to the atmospheric pressure, which depends on the needs of the thermal load. This is why the term backpressure is used. It is also possible to extract steam from intermediate stages of the steam turbine, at a pressure and temperature appropriate for the thermal load. After the exit from the turbine, the steam is fed to the load, where it releases heat and is condensed. The condensate returns to the system with a flow rate which can be lower than the steam flow rate, if steam mass is used in the process or if there are losses along the piping. Make-up water retains the mass balance.

-

Extraction Condensing Steam Turbine

In such a system steam for the thermal load is obtained by extraction form one or more intermediate stages at the appreciate pressure and temperature, the remaining steam is exhausted to the pressure of the condenser, which can be as low as 0.05 bar with a corresponding temperature of about 33 C. It is rather improbable that such low temperature heat finds useful applications. Consequently, it is rejected to the environment. In comparison to the backpressure system, the condensing type turbine has a higher capital cost and, in general, a lower total efficiency. However, to a certain extent, it can control the electrical power independent of the thermal load by proper regulation of the steam flow rate through the turbine.

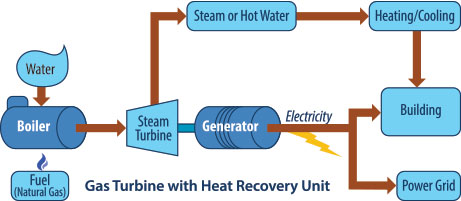

2. Gas Turbine Cogeneration System

Gas turbine system operates on the thermodynamic cycle known as the Brayton cycle. In a Brayton cycle, atmospheric air is compressed, heated and then expanded, with the excess of power produced by the turbine or expander over that consumed by the compressor used for power generation.

-

Open-cycle Gas Turbine Cogeneration Systems

Most of the currently available gas turbine systems, in any sector of applications, operate on the open Brayton (also called Joule cycle when irreversibility’s are ignored) cycle where a compressor takes in air from the atmosphere and derives it at increased pressure to the combustor. The air temperature is also increased due to compression. cogeneration system provide help to understand of integrated power generation and genration planning.

-

Closed-cycle Gas Turbine Cogeneration Planning

In the closed-cycle system, the working fluid (usually helium or air) circulates in a closed circuit. It is heated in a heat exchanger before entering the turbine and it is cooled down after the exit of the turbine releasing useful heat. Thus, the working fluid remains clean and it does not cause corrosion or erosion. Source of heat can be the external combustion of any fuel. In addition, nuclear energy or solar energy can be used.

3. Reciprocating Engine Cogeneration System

Reciprocating engines are well suited to a variety of distributed generation applications, industrial, commercial and institutional facilities for power generation and CHIP. Reciprocating engines starts quickly, follow load well, have good part-load efficiencies and generally have high reliabilities. In many cases, multiple reciprocating engine units further increase overall plant capacity and availability. Reciprocating engines have higher electrical efficiencies than gas turbines of comp ratable size and thus lower fuel- related operating costs.

Hence these are Integrated power generation and generation planning . we studied about the differet benifit of integrated power generation and generation planning.we have also known about the method of cogeneration system. If you will find any incorrect in above article please comment in comment box.