General Description Of Pumped Storage Plants

General Description Of Pumped Storage Plants

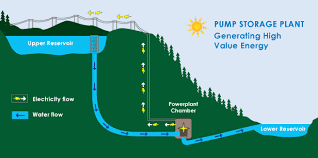

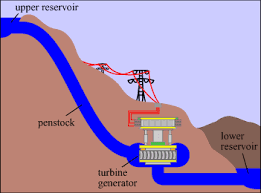

A pumped storage plant is a special type of plant meant to supply peak loads. During peak load period, water is drawn from the head water pond through the penstock and generates power for supplying the peak load. During the off-peak period, the same water is pumped back from the tail water pond to the head water pond so that this water may be used to generate energy during the next peak load period. Thus, the same water is used again and again and extra water is needed only to take care of evaporation and seepage. Generally the pumping of water from the tail water pond to the head water pond is done at night when loads are low. The plant generates energy for supplying peak loads during day time. The off peak pumping maintains the firm capacity of the pumped storage plant. The reservoir capacity should be such that the plant can supply peak load for 4 to 11 hours. A general arrangement of pumped storage plant .

The earlier pumped storage installations used a separate pumped of pumping the water back into the head water pond. A recent development is a reversible turbine pump. During peak loads, the turbine drives the alternator and the plant generates electrical energy. During low loads, the alternator runs as a motor and drives the turbine which now works as a pump for pumping the water into the head water pond. This arrangement reduces the capital cost of the plant. The power for driving the motor is taken from the system.

PUMPED STORAGE PLANTS FOR SUPPLYING PEAK LOADS

Every pumped storage scheme reduces dual conversion of energy, the efficiency being around 60 to 70 percent. The fact that the energy gained from a pumped storage plant is always less than the energy input, should not obscure the fact that this apparent loss to the system is negligible when compared with the substantial savings in fuel which are made when these plants are used in a mixed system. The most obscures economies are in the replacement of standby thermal plants and in the fact that the existing thermal plants can be run with fewer and less rapid load changes.

Modern generation systems are a mixture of hydro, steam and nuclear power stations so that energy can be generated most economically. If hydro contribution is small, the steam and nuclear stations have to be of sufficiently large capacity. The steam and nuclear plants operate more economically when run continuously at or near full load. At the time of low loads the excess energy generated by stem and nuclear plants can be used for driving the motor of the pumped storage scheme. The pumped storage plant would in turn supply peak loads. Thus the capacity of the steam and nuclear plants need be only for supplying the base loads and hence much less than what it would be if they were to meet the whole demand. In addition the steam and nuclear plants can be worked at almost unity load factor which ensures their most economic operation.

Advantages Of Pumped Storage Plant

Pumped storage plants have very important advantage. Some of these are:

(i)

Peak loads can be supplied at a lesser cost that that incurred when these loads are supplied by steam and nuclear plants.

(ii) Standby capacity is available on short notice. Power engineers in utilities having pumped storage installations have long realized the benefit of quick switching on and off capacity of these installations. Pumped storage plants need a starting time of only 2 to 3 seconds and can be loaded fully in about 15 seconds. In the event of an outage on a unit, a pumped storage plant can be called upon to meet the generation deficiency (occurring due to the outage) thus ensuring reliable supply and avoiding the necessary of load shedding.

(iii) The load factor of steam and nuclear plants is increased thus ensuring their efficient and economic operation.

(iv) Since the base loads plants needs not be used to supply peak loads. The forced and maintenance outages of these plants are likely to be reduced.

(v) In the event of an extra demand coming up suddenly on the system, these plants can be immediately switched on to meet this extra demand.

(vi) Because of their ability to take up loads in a very small time, the use of pumped storage plants reduces the spinning reserve requirement of the systems.

(vii) They can be used for load for frequency control.

Types Of Pumped Storage Installation

Pumped storage plants offer many benefits. However their feasibility and economics should be critically evaluated at the planning stage. During the power system planning studies, three types of pumped storage installation can be considered:

(i) High head, daily daily/weekly cycle, peaking plants close to the load center.

(ii) Low/medium head, seasonal cycle plants, far-away from load center (peaking or non-peaking types).

(iii) Medium head, daily/weekly cycle peaking plants at an existing cascade of reservoirs.

Hence these are basic description of pumped storage plant if you will find any incorrect in above article you must comment below in comment box.